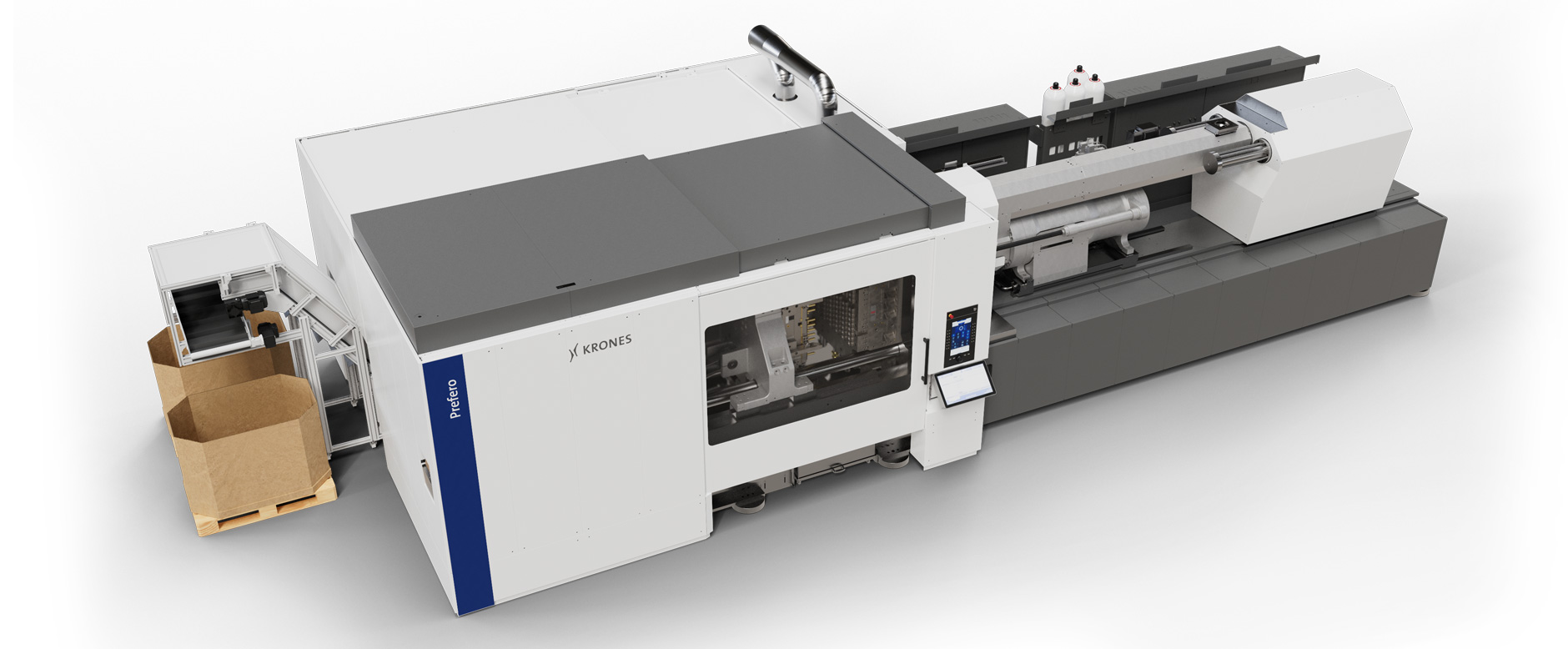

The Prefero PET injection moulding machine

Prefero is the core of the Krones preform system. The injection moulding machine is designed as a hybrid machine with electrical positive locking movement. Prefero is not only impressive with a best-in-class lock-to-lock time of a quick 1.9 seconds (400 t). Thanks to an integrated energy recovery system, up to 20 percent of the total energy consumption can be saved as compared to competitors' machines.

- Lock-to-lock time of a quick 1.9 seconds (400 t)

- Lateral removal unit with post-cooling system

- Preform interior cooling system

- Energy recovery from positive locking and robot movement reduces the total energy consumption by up to 20 percent*.

- Processing of 100 % rPET is possible.

*Compared to similar machines of the competition

Design

Side entry – take out robot with post mould cooling

Electrical operated mould opening and closing (energy efficient toggle system)

Plasticizing unit with the newest designed screw for better melt quality and 100% rPET processing at high throughputs

Easy access mould area

Intelligent Hydraulic Unit with adaptive drive

Tailor-made operator panel (HMI) for preform production systems

Your benefits to your own preform production

In-house manufacturing offers reliability

- Supply chain security

- Process control (FiFo)

- Quality and hygiene in your own hands

- Cost control

Cost reduction

- Optimisation of storage capacity and handling

- Reduction of transport costs and logistics

- Material saved thanks to optimised preform design

- Energy and CO2 saving due to lower logistical effort

Preform design depending on bottle and application

- Tailor-made light-weight packaging solutions

- Higher preform quality

- Process reliability

Larger process window for more efficiency on the entire line