High-end variant for filling clear spirits and liqueurs in glass bottles

- Determination of the fill level via vacuum correction

- No direct contact of the vacuum with the product: it is guided via a separate vacuum channel

- The product is not returned to the ring bowl during the correction phase

- Operates according to the “no bottle, no filling” principle

- Changing the fill level via an adjustable filler top part

- Electropneumatic filling valve

- One filling speed

- Filling valve integrated in the CIP circuit

Fields of application

- Suitable for clear spirits and liqueurs

Output

- Up to 60,000 containers per hour

HVT = Height filling system, Vacuum, Tube-in-tube

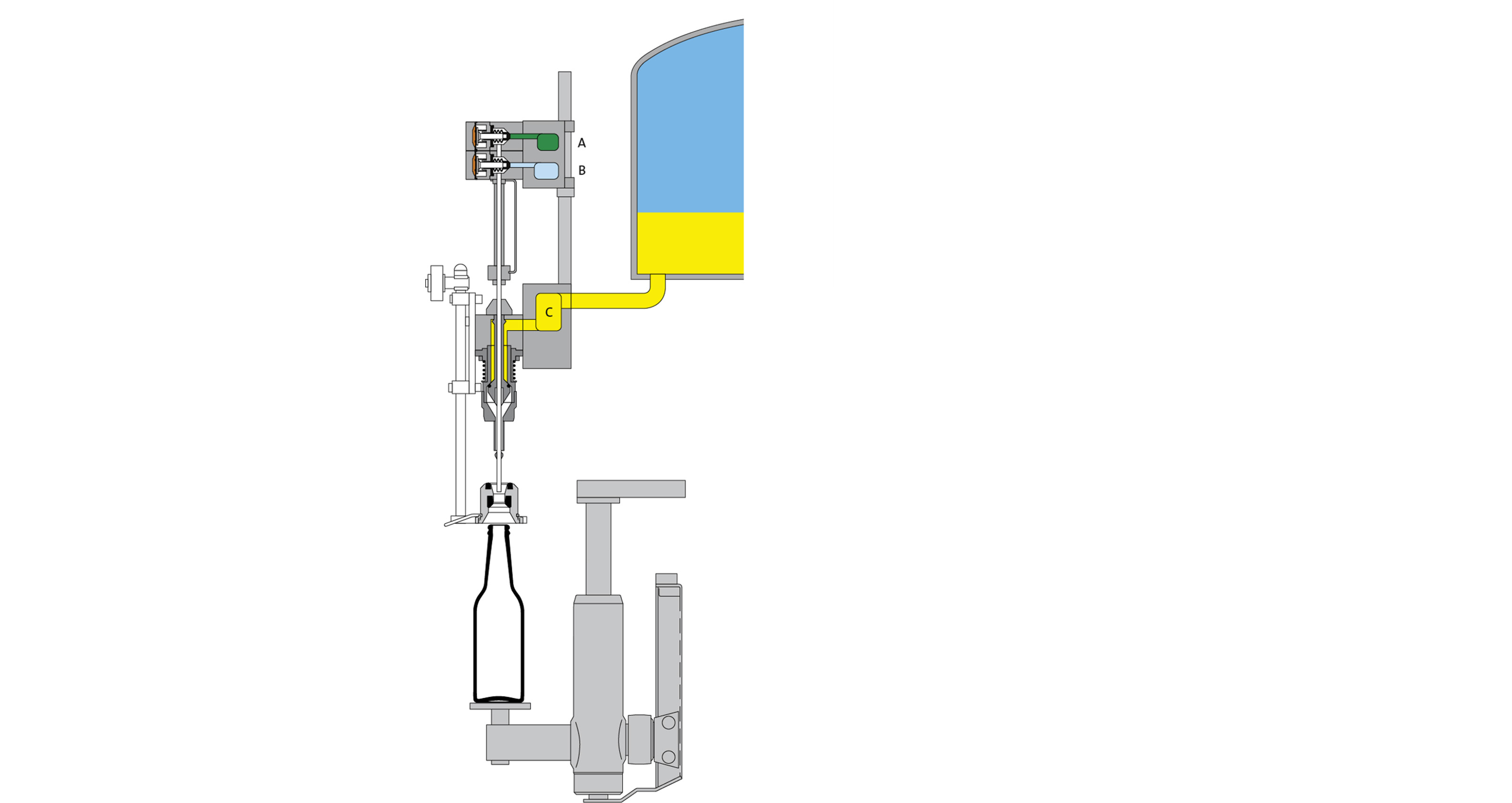

Functional principle of the valve

The Modulfill HVT is a mechanical filling system which operates with a correction tube. The bottle is pressed onto the filling valve. Then the valve opens and filling begins. As soon as the bottle is full to the brim, the valve closes and the electropneumatically controlled vacuum correction begins. The correction quantity is drained into a separate channel. Since the valve function is controlled by the bottle, the following principle is valid: "no bottle, no filling".

Pressurisation and return gas valve

Product stem

Snifting channel (CIP return channel)

Pressurising and return gas channel

Product channel

Filling tube with inner return air tube

Valve stem

Product tank

Benefits to you

Practically no loss of alcohol (intensity)

-

Vacuum filling technology with separate vacuum channel

Highest product purity

-

No return of the product to the ring bowl during the correction phase

Almost no product loss

-

Return of the product via troughs to a rework tank

Maximum filling accuracy

- Vacuum correction

- Low standard deviation of the fill level

- No product loss

High operator friendliness

- Automatic adjustment to new bottle heights

- Highest flexibility for change-overs

- Automatic vent pipe adjustment

Observance of safety regulations

- Requirements for protection against explosions are met

Variable filling speeds

- The speed is increased through overpressure filling

- Two filling speeds possible

How can we help you?

Additional information

Download

Do you have any questions?

Contact

Krones nearby you

Sales network

Come and visit us

Events