For soft drinks: Filling valves with flow meters

Range of applications

- Juice and tea products in high and low-acid range

- Products with

- Particles up to 5 x 5 x 5 millimetres

- Fibres up to 2 x 10 mm

Technical features

- Non-contact full-jet filling

- Inductive flow meter for determining the quantity of liquid

- Two different filling speeds via product-gentle double-stroke seat valve

- Non-turbulent closing of the filling valves thanks to double-stroke seat valve

- Product feed from above via a sliding ring manifold

- Sterilisation with steam

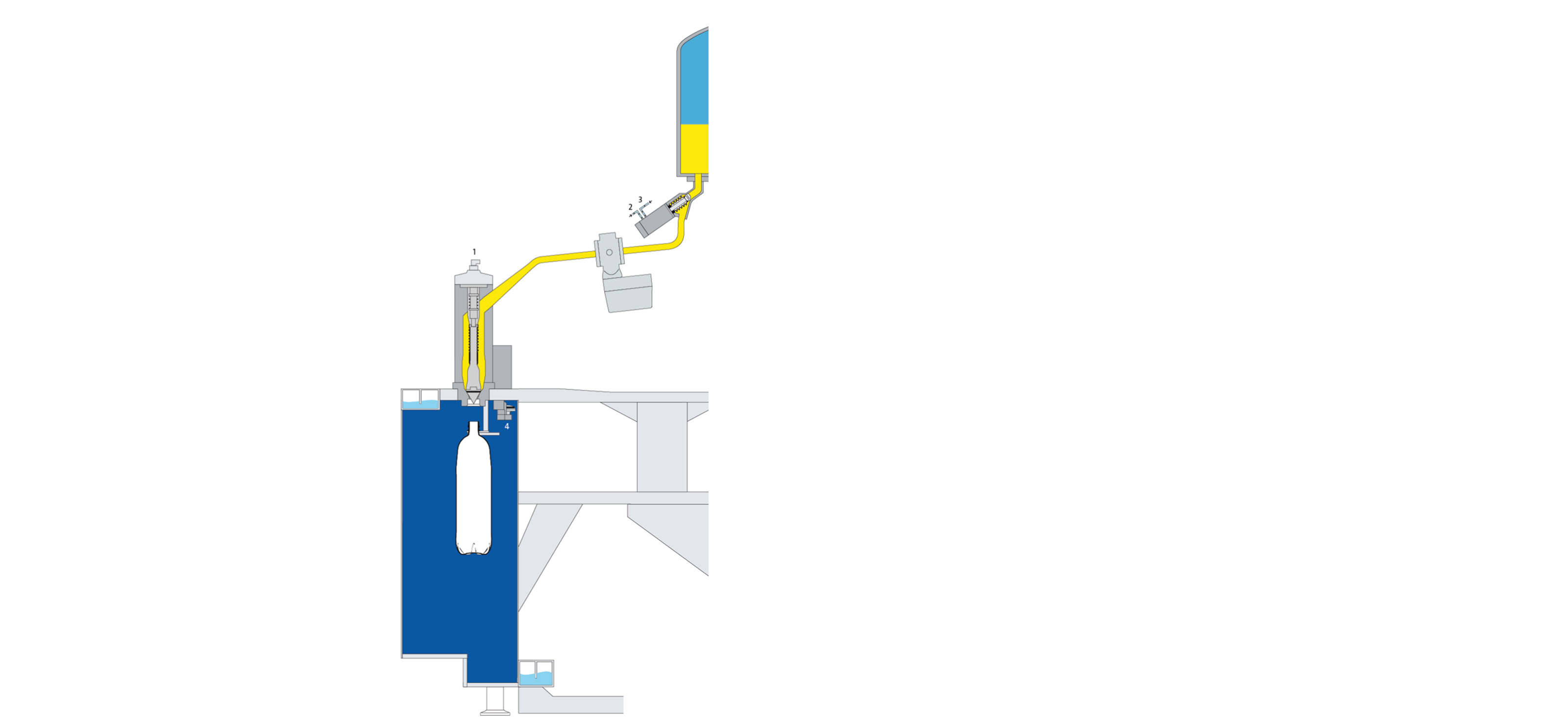

VFJ: Volumetric filling, Flow meter, full Jet

Filling valve

Aseptic area

SIP cup

Hydraulic seal “Liquid seal system”

Valve stem

Pneumatic cylinder

Valve stem control cylinder

Inductive flow meter

Product discharge valve

Switching valve for fast/slow filling

Central bowl

Benefits to you

- High microbiological safety

- Precise fill quantities

- Optimum flow behaviour

- Smooth filling process which is gentle on the product

- Minimum product loss

- Quick and media-efficient disinfection

- No CIP distributor needed

How can we help you?

Additional information

Download

Do you have any questions?

Contact

Krones nearby you

Sales network

Come and visit us

Events